ControlSoft Simplifies Extrusion Barrel Temperature Control

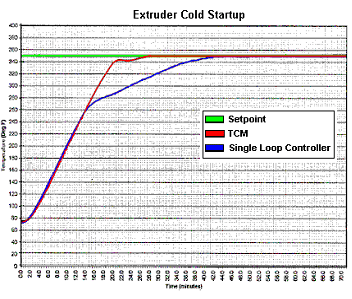

One of the most difficult and commonly seen control problems is the proper control of slow temperature loops. This is because of the large mass of material that these loops usually involve. In a heating loop, for example, both heating power and time are required to heat the system (long deadtime issues). Then, once the temperature starts to rise, it will increase slowly but steadily, and will tend to continue to increase for some time, even after the heating device has been turned off due to the problem of thermo momentum. Hence, one often ends up with a large overshoot and oscillatory response (with a very long cycle time).

Such a problem is further aggravated in Extrusion Barrel Temperature control because there are typically multiple barrel zones in an extruder. While each zone behaves differently, they also affect each other. The cooling process further complicates the issues since cooling and heating behave very differently. Finally, shear energy from the screw also affects temperature within the system.

MANTRA Software includes a specially designed control strategy incorporated in the Temperature Control Module (TCM) such that each stage of the control is treated differently, since different requirements are imposed at different stages, such as tuning stages, start-up stage, initial control stage, and run-time production control. With the use of TCM, all these internal stages are transparent to users. After configuring the TCM block, only one start button is required for a user to commission TCM control.

ControlSoft’s Solution – Mantra Temperature Control Module

TCM is an advanced control solution that takes into account all the challenges of extruder temperature control, specifically:

- TCM treats different zones differently, since they behave differently.

- TCM takes into account that neighboring zones may affect each other, and it coordinates the control among all zones.

- TCM provides different controller speeds, user selectable.

- TCM uses model predictive control techniques to better control and predict the temperature.

- TCM uses different sets of tuning parameters for startup and steady-state.

- TCM performs auto-tuning during the start-up time; no additional tuning test is required.

- TCM provides independent heat/cool control with proper coordination.

- TCM is applied as supervisory control over the existing control system.

As the Figure illustrates, even a well-designed PID cannot match the performance of the MANTRA TCM block.

Key Advantages of the ControlSoft TCM Technology over Traditional PID Controllers

- Provides a fast startup from cold position with minimum overshoot to minimize startup time.

- Provides tight temperature control during production (+/- a few degrees versus significant oscillations with PID controllers) for more consistent product quality and optimal utility usage.

- Provides a fast response for product or setpoint changes to minimize the time to reach stable production temperatures.

- Handles the dynamics of heating and cooling independently.

- Contains self-tuning function to minimize implementation time.

ControlSoft’s solutions featuring MANTRA TCM technology can increase the profitability of your process with no replacement of existing hardware or wiring required.