Realize Energy and Cost Savings

The use of variable frequency drives (VFDs) in flow control applications is gaining in popularity and eroding the hegemony of traditional control valves. Energy efficiency is the main reason for this change producing multiple economic payouts, although there may be benefits to process dynamics as well. VFDs are used to control the speed of motors which are frequently used to drive pumps, fans, and compressors. Typically, a VFD operates by receiving a speed setpoint, usually from a DCS (Distributed Control System) or PLC (programmable logic controller), and compares the setpoint to the actual motor speed. When there is a discrepancy, the VFD adjusts the electrical power to the motor in order to get the actual speed to match the setpoint. As with any control application, proper tuning of a VFD is critical.

Achieve the Best Results from Your VFD Installation

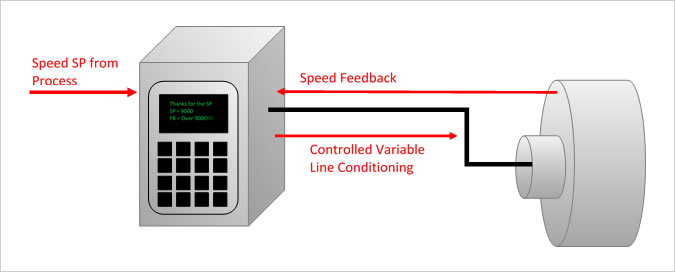

In considering a VFD in place of a control valve, a VFD will operate with faster dynamics while avoiding common valve problems such as hysteresis and stiction. When talking about VFD tuning, it may be helpful to think of cascade control. Process control usually controls variables such as flow rate, temperature, pressure, level, and product composition. Motor speed (which is controlled by the VFD) can be thought of as the inner loop in a cascade control scheme with the outer loop controlling one of the aforementioned variables. Control of the outer loop is most commonly handled by a standard PID controller. Figure 1 illustrates a common VFD controller implementation. The relationship between the process’s controlled variable and the motor speed should be determined by plant tests. Once this relationship has been established, the optimal tuning parameters for the outer loop can be calculated in order to achieve the best results from your VFD installation. ControlSoft’s INTUNE software is frequently used for such tests and tuning.

Figure 1: VFD control viewed as its own inner loop in cascade control.

It should be noted that some applications that employ VFDs may also require the installation of a control valve to provide safe and reliable operation across the entire range of a controlled variable. To this point, VFDs are not immune to dead heading and may require a recirculation valve, as well as an on-off and/or check valve. A system curve can have high static head but little friction head, while a pump curve can be low sloped or even drooping, depending on both geometry and fluid properties. This could lead to an unstable operating region and is one reason to consider keeping a control valve after a VFD. Such an arrangement allows both the pump and system curve to be under control. As shown in figure 2 below, this allows for a wider operating range for both pressure and flow. In this example, a VFD can reduce the flow from 76% to 23%, but begins to risk unstable operation in the 23% range as the proximity of the curves becomes dangerous. If flow in this range is desired, it would be safer to keep the pump curve higher and use a control valve to reach low flows such as 8%. A back pressure valve is shown here to demonstrate the flexibility in pump curve ranges, but a recirculation valve may be used to similar effect.

Figure 2: Split range control of flow by VFD speed and throttling.

Such an installation might employ split range control with a lower VFD limit on speed. Depending on system dynamics and constraints, a more elegant solution might be to employ a Coordinated Control (CC) algorithm like that found in ControlSoft’s MANTRA control system. With a CC implementation, the controller will act to 1) provide the tightest control possible in the short term while 2) minimizing energy consumption in the long term. Figure 3 illustrates that, for a certain flow setpoint, there is a continuum for valve position and motor speed. Cost is minimized by reducing power, which is reduced with motor speed. A CC will always drive the system toward the operating point that maximizes cost savings, so toward reduced speed in this case, while remaining within operating constraints and balancing other considerations.

Figure 3: A Coordinated Control (CC) system maximizes cost savings and minimizes power consumption.

Proper tuning of controllers is of paramount importance if the operator is going to reap the economic benefits from a VFD installation. ControlSoft offers a number of tools to address this situation. From our INTUNE PID tuning tools which assist in finding the best tuning parameters for your controllers to our Coordinated Control algorithm (which effectively deals with multiple manipulated variables controlling a single process variable) ControlSoft can help to ensure the proper operation of your VFD installation. Effective VFD process control requires a good understanding of all relationships and interactions between a VFD, control valves, and the controlled variable.

Optimize Your VFD Performance

The popularity of VFDs has increased dramatically in recent years as plant operators strive to achieve maximum efficiency from their operating equipment. The financial impact that VFD operation has on electrical power usage is often a KPI (Key Performance Indicator) that is tracked and reported by a plant’s Control Loop Performance Monitoring (CLPM) system. The potential for savings is very real, but a large capital investment in VFDs might be lost without good process control.

ControlSoft, Inc. is here to make sure you get the full value out of your installed equipment and capital projects. We offer a wide range of products and services to help you plan, implement, and optimize process control. Our INTUNE tuning tools is ideally suited for determining optimal tuning parameters for the most difficult applications, including VFDs and more. Our INTUNE+ control loop monitoring system can track and report detailed statistics regarding your control system’s performance, while also defining and reporting on KPIs. Our engineers have hundreds of man-years devoted to helping our clients improve all aspects of their process control systems. We would be pleased to discuss with you how we can help you achieve your own operating goals.

We would be pleased to discuss with you how we can help you achieve your operating goals. Contact us today!